A Full Service, Precision Machine Shop

Trust in our dedicated team, specialized equipment,

and 16,000 square foot facility.

Guaranteeing superior quality & lasting relationships

Tri-Kris is a family owned precision machine shop that has been meeting and exceeding the needs of customers for more than sixty years. Our extremely qualified workforce and 16,000 square foot facility allows Tri-Kris to maintain quality manufacturing capabilities while keeping up with the demand of all our customers.

The Tri-Kris staff has grown to target their expertise in three main areas:

designing and creating prototypes, repairing existing components, and can run 1 to 10,000 piece production lots.

With a close knit work environment our supervisors and other employees work hand-in-hand to make sure that every final product is exactly what the customer asked for.

We also maintain a healthy business relationship with our suppliers, which allows us to offer some of the most competitively low prices in the area.

Our Services

Repairs

Repairs

Repairs

Bar Stock & Plate

Bar Stock & Plate

Bar Stock & Plate

Castings/Forging

Castings/Forging

Castings/Forging

Welding & Fabrication

Weldments & Fabrications

Weldments & Fabrications

Inspection

Inspection

Inspection

Value-Added Services

Value-Added Services

Value-Added Services

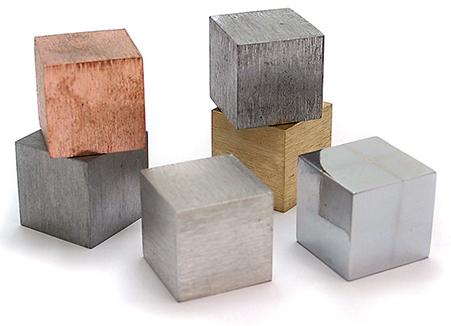

Our Materials

We have built very healthy working relationships with all of our vendors, which has helped ensure consistent quality, consistently low prices and timely delivery every time. Some of the materials we use but are not limited to include: steel, alloy steel, tool steel, cast iron, aluminum, bronze, brass, 300 and 400 series stainless steel, 17-4, 13-8, 18-8, duplex stainless, monel, inconel, hastalloy, titanium, stellite, tantalium and zirconium.